The working principle of the laser galvanometer is that the laser beam is incident on two reflectors (scanning mirrors), and the reflection angle of the reflectors is controlled by a computer. The two reflectors can scan along the X and Y axes respectively, so as to achieve the deflection of the laser beam, so that the laser focus with a certain power density moves on the marking material according to the required requirements, thereby leaving a permanent mark on the surface of the material. The focused spot can be circular or rectangular.

Model: Laser galvanometer

Specifications: Customized

Material: Optical glass

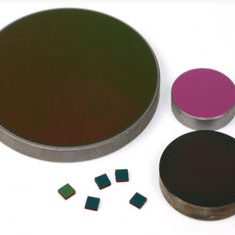

GIAI uses imported coating equipment and ion sputtering coating technology, which has the characteristics of high film strength, good spectral uniformity, and strong central wave stability. The specifications and sizes can be customized according to customer requirements, both square and round shapes are available.

Product advantages

Fast response speed;

High marking speed;

High marking quality;

Good optical path sealing performance;

Strong adaptability to the environment.

Application fields

Simply speaking, the galvanometer system is a high-precision, high-speed servo control system composed of a drive board and a high-speed swing motor. It is mainly used for laser marking, laser engraving, stage lighting control, laser drilling, etc.