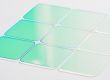

Infrared temperature measurement filters are optical filters specially designed for infrared bands and are commonly used in non-contact temperature measurement equipment. They can selectively transmit infrared radiation and filter out interference light from other bands, thereby achieving high-precision temperature detection. This article will introduce in detail the types, working bands, application parameters and typical application scenarios of infrared temperature measurement filters.

1.Types of infrared temperature measurement filters

Infrared temperature measurement filters are a type of bandpass filter.

Bandpass filters allow light in a certain wavelength range to pass through, while blocking spectral signals outside the band. Through optimized design and precision manufacturing, infrared temperature measurement filters can selectively transmit specific infrared bands and filter out the interference of ultraviolet and visible light on the measurement.

According to the materials and manufacturing process, infrared temperature measurement filters can be further classified into:

Interference filters: selective transmission of specific bands is achieved through the interference effect of multi-layer optical films, with high transmittance and narrow bandwidth.

Absorption filters: filtering is achieved by using the absorption characteristics of special materials for light in specific bands, but usually the transmittance and thermal stability are lower than those of interference filters.

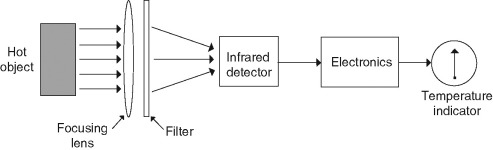

1.1 Working principle of infrared thermometer

An infrared thermometer uses a lens system to focus radiation onto an infrared detector that converts the energy absorbed into an electrical signal. The temperature inferred from the electrical signal is corrected for the emissivity of the source. Using optical filters, infrared thermometers may employ a very narrow range of wavelengths, whereas other systems may use a very broad range of wavelengths. In either case, the energy absorbed is related to temperature using Planck’s law. Broadband infrared spectrometers are relatively inexpensive and easy to use, but their accuracy suffers from the fact that emissivity depends on wavelength, thereby making corrections difficult. Narrow-band infrared thermometers do not face this limitation because the emissivity value does not vary appreciably over the wavelengths used.(Explore the Principles of Infrared Thermometers)

2.Common application bands

The design of infrared temperature measurement filters needs to be based on the working band of the target temperature measurement equipment, which generally includes the following common bands:

2.1. Near infrared (NIR, 0.75–1.4 μm)

Applied to short-wave infrared temperature detection, suitable for the measurement of high-temperature bodies (such as furnaces, metal processing).

Advantages: Strong penetration, can penetrate smoke and water vapor under certain conditions.

2.2. Mid-infrared (MIR, 3–5 μm)

Applied to gas analysis and low-temperature thermal radiation detection, suitable for temperature monitoring of medium and high temperature targets, such as industrial thermal processes and medical thermal imaging.

Advantages: Strong response to the radiation peak of the target object and high sensitivity.

2.3. Far infrared (FIR, 8–14 μm)

The most common temperature measurement band, used in human body temperature detection, environmental temperature measurement and other fields.

Advantages: Covers the peak range of thermal radiation of the target object, suitable for most non-contact temperature measurement applications.

3.Key parameters of infrared temperature measurement filters

The performance of infrared temperature measurement filters is determined by multiple optical parameters, which directly affect their application effects:

3.1. Center Wavelength (CWL)

Refers to the center value of the spectral range that the filter allows to pass (in nanometers or micrometers).

Typical range: Depending on the application, common center wavelengths are 940 nm (near infrared), 3.9 μm (mid-infrared) or 10.6 μm (far infrared).

3.2. Bandwidth (FWHM, Full Width at Half Maximum)

Reflects the spectral selectivity of the filter and is defined as the spectral width when the transmittance reaches half of the peak value.

Usually, the bandwidth is narrow (such as 10–50 nm), which helps to improve temperature measurement accuracy and reduce ambient light interference.

3.3. Transmission

The light transmittance of the filter within the target band range. High transmittance (>90%) is the key to ensuring the strength of the infrared signal.

3.4. Blocking Depth

Refers to the blocking effect of the filter in the non-target band, usually expressed by the OD value (optical density): OD=−log10(T)OD = -\log_{10}(T) For example, OD4 means the transmittance is as low as 0.01%.

3.5. Environmental adaptability

Temperature resistance: The filter must be able to withstand the high temperature environment in which the equipment is running.

Moisture resistance: The spectral performance must remain stable under high humidity conditions.

4.Typical application scenarios of infrared temperature measurement filters

4.1. Industrial temperature measurement

In the manufacturing industries such as steel, glass, and ceramics, infrared temperature measurement filters help to achieve accurate temperature monitoring of high-temperature furnaces and products to ensure production quality.

4.2. Medical temperature detection

The core components of non-contact thermometers such as infrared ear thermometers and forehead thermometers quickly and accurately measure human body temperature based on the far-infrared 8–14 μm thermal radiation spectrum.

4.3. Environmental monitoring

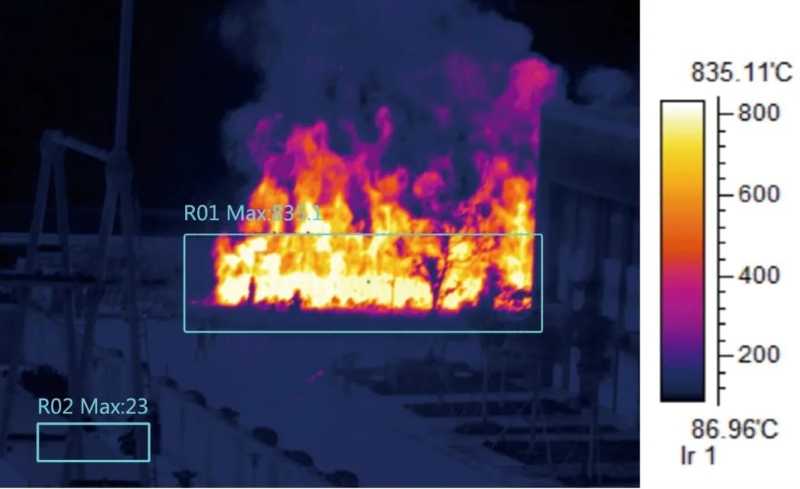

Used to monitor environmental temperature changes, heat source distribution, etc., such as in weather stations and forest fire warning systems.

4.4. Thermal imaging equipment

Infrared filters are used with thermal imagers to capture infrared radiation on the surface of objects and are widely used in night vision, security, medical imaging, and building heat loss detection.

4.5. Aerospace

Infrared temperature measurement filters are used in remote sensing technology to analyze thermal characteristics by detecting infrared radiation from the earth’s surface or objects in space.

5.Future development of infrared temperature measurement filters

With the development of infrared technology, infrared temperature measurement filters are being optimized in the following directions:

Wider operating temperature range: meet the needs of extreme industrial and aerospace environments.

High light transmission efficiency and wide spectrum compatibility: further improve transmittance while supporting multi-band applications.

Intelligent integration: combine filter and sensor technology to achieve more compact and higher performance infrared temperature measurement equipment.

6.Conclusion

As a key component in non-contact temperature measurement equipment, the performance of infrared temperature measurement filters directly affects the accuracy and reliability of temperature measurement. Through optimized design and precision manufacturing, this type of filter can meet the diverse needs from industry to medicine, from environmental monitoring to aerospace. In the future, with the advancement of optical materials and manufacturing processes, infrared temperature measurement filters will play an important role in a wider range of fields and provide strong support for high-precision temperature detection.