Optical filters are important components in modern optical systems and are widely used in optical instrument fields such as scientific research, industrial production, biomedicine, and communication technology. In the manufacturing process of optical filters, the selection of substrate optical materials is crucial because their performance directly affects the optical properties, environmental adaptability, and service life of the filters. This time, we will take you to a simple understanding of the optical substrate of the filter by making a preliminary understanding of the filter substrate.

1.The role of optical materials in optical filters

The performance of the filter depends on the combined effect of the substrate and the coating layer. The substrate optical material not only needs to meet the requirements of optical performance, but also needs to have good mechanical strength, chemical stability, and thermal stability.

The substrate mainly plays the following roles:

Optical performance basis: The refractive index, transmittance, and dispersion characteristics of the substrate determine the transmission spectrum range and performance of the filter.

Mechanical support: The substrate provides structural support, allowing the filter to be stably used in various environments.

Environmental adaptability: In some application scenarios, the filter needs to withstand environmental challenges such as high temperature, humidity, and chemical corrosion, and the physical and chemical properties of the substrate must adapt to these conditions.

2.Common filter substrate optical materials

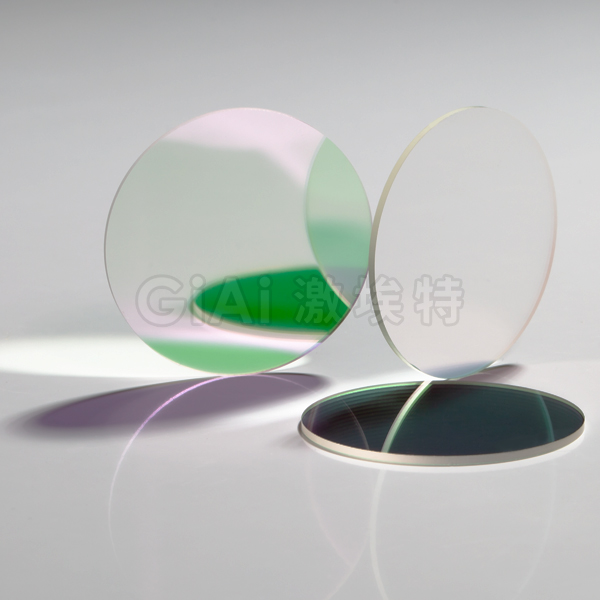

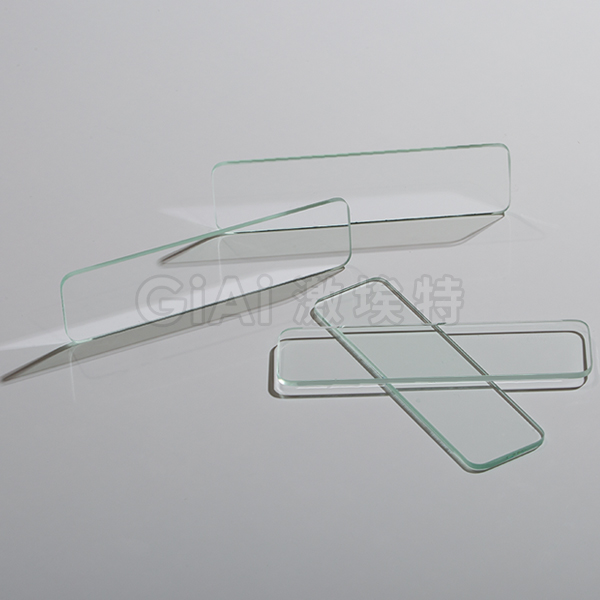

Optical glass

Optical glass is one of the most commonly used substrates for filters. Due to its excellent optical properties and diverse choices, it is suitable for various filter manufacturing needs.

Features:

High transmittance: It has good light transmittance in the visible and near-infrared bands.

Uniformity: The internal structure of optical glass is uniform and the optical properties are stable.

Processability: It is easy to cut, polish and coat.

Common types and uses:

BK7 glass: It has stable refractive index and high transmittance, and is widely used in neutral density filters and bandpass filters.

Fused Silica: It is resistant to high temperatures and has a low thermal expansion coefficient. It is an ideal choice for high-precision filters.

High refractive index glass: It is used for filters that require high refractive index and high dispersion performance, such as narrowband filters.

Crystal materials

Some special filters require the use of crystal substrates, such as polarizers or infrared filters.

Features:

Wide spectral range: Crystal materials usually have a wider transmission spectral range, covering the ultraviolet and infrared bands.

Good optical anisotropy: suitable for manufacturing polarized optical devices.

Common materials:

Quartz crystal: has excellent UV transmittance and is used for UV bandpass filters.

Zinc sulfide (ZnS) and zinc selenide (ZnSe): suitable for infrared filters, especially long-wave infrared band applications in thermal imaging systems.

Plastic optical materials

Plastic substrates are often used in some consumer-grade filters with low optical performance requirements due to their lightweight and cost advantages.

Features:

Lightweight: suitable for portable optical devices.

Easy to process: complex shapes can be manufactured by injection molding.

Low cost: suitable for large-scale production.

Common materials:

Polycarbonate (PC): good impact resistance, suitable for filters in sports camera equipment.

Acrylic acid (PMMA): high transmittance, but poor heat resistance.

3.Selection basis of filter substrate optical materials

The selection of filter substrates needs to comprehensively consider the application scenarios and optical performance requirements. The following are some key factors:

Optical performance: including refractive index, transmittance and dispersion characteristics.

Environmental adaptability: temperature resistance, corrosion resistance and moisture resistance.

Mechanical properties: hardness, strength and impact resistance.

Processability: whether it is easy to cut, polish and coat.

Cost and large-scale production: high-performance materials are often expensive, and the cost performance needs to be weighed according to actual needs.

4.Future development trends

With the advancement of optical technology and the continuous expansion of application fields, filter substrate optical materials are also developing:

New material development: nanomaterials, composite materials and photonic crystal materials will gradually be introduced into the filter manufacturing field.

Environmental protection materials: reduce the use of heavy metals and develop greener and more environmentally friendly optical materials.

High-performance substrates: meet the needs of high-power lasers, extreme environments and wider spectral ranges.

5.Conclusion

The optical material of the filter processing substrate is the basis of the filter performance, and its performance directly determines the application effect and life of the optical filter. By selecting the right substrate and combining it with advanced coating technology, filters can meet the increasingly complex needs of modern optical systems. In the future, with the development of material science and manufacturing technology, filter substrate optical materials will bring more innovations and breakthroughs to the optical industry.