Detailed Product Description

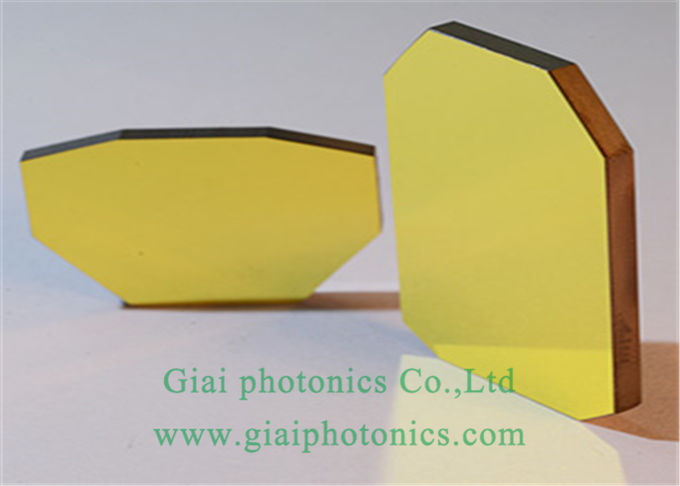

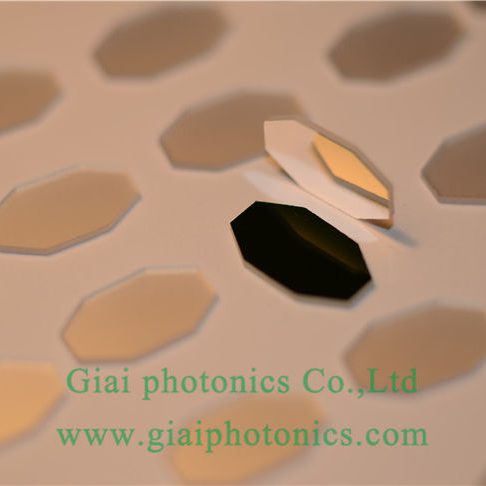

| Product Name: | Polished Infrared Lens | Material: | Silicon |

|---|---|---|---|

| Color: | Red | Laser Type: | CO2, YAG 1064nm, 532nm, 355nm |

| Size: | Customization | Application: | Laser Precision Welding |

Dual Axis Optical Galvanometer Scanners for Diode Laser Marking Machine

Dual Axis Galvanometer Optical Scanners

Specifications:

| Type of Optics | Mirror Size: 3mm Aperture |

| Coating | 1000Å Thick Low Pinhole, Protected Silver |

| Current – Peak (A) | Maximum: 8 |

| Current – RMS (A) | Maximum: 2.4 |

| Power – RMS (W) | Maximum: 30 |

| Damage Threshold, CW (W/cm2) | 150 – 200 |

| Maximum Drive Current (A) | 10 @ Peak, 5 @ RMS |

| Substrate | Silicon |

| Rated Excursion, Rotor (°) | ±20 |

| Bumper Stop Angle, Initial Contact (°) | ±26 |

| Rotor Inertia (gm-cm2) | 0.018 |

| Torque Constant (dyne-cm/A) | 27900 |

| Coil Resistance (Ω) | 3.72 |

| Coil Inductance (μhenries) | 109 |

| Back EMF Voltage (μV/°/s) | 48.7 |

| Position Signal (V) | ±10 |

| Dimensions (inches) | 3.95 L x 3.05 W x 1.21 H |

| Operating Temperature (°C) | 0 to +50 |

| Power Requirement | ±15 to ±28V DC |

| RoHS | Compliant |

| Type of Optics | Mirror Size: 3mm Aperture |

| Coating | 1000Å Thick Low Pinhole, Protected Silver |

| Current – Peak (A) | Maximum: 8 |

| Current – RMS (A) | Maximum: 2.4 |

| Power – RMS (W) | Maximum: 30 |

| Damage Threshold, CW (W/cm2) | 150 – 200 |

| Maximum Drive Current (A) | 10 @ Peak, 5 @ RMS |

| Substrate | Mirror: Fused Silica |

| Rated Excursion, Rotor (°) | ±20 |

| Bumper Stop Angle, Initial Contact (°) | ±26 |

| Rotor Inertia (gm-cm2) | 0.018 |

| Torque Constant (dyne-cm/A) | 27900 |

| Coil Resistance (Ω) | 3.72 |

| Coil Inductance (μhenries) | 109 |

| Back EMF Voltage (μV/°/s) | 48.7 |

| Position Signal (V) | ±10 |

| Dimensions (inches) | 3.95 L x 3.05 W x 1.21 H |

| Operating Temperature (°C) | 0 to +50 |

| Power Requirement | ±15 to ±28V DC |

| RoHS | Compliant |

Description:

Dual Axis Galvanometer Optical Scanners provide superior positioning speed and accuracy precision than comparable compact, cost-sensitive, closed loop galvanometers. Featuring low inertias, compact sizes, and high speeds and accuracies, these galvos are ideal for applications including biomedical systems, optical coherence tomography, laser projection, confocal microscopy, and analytical instrumentation.

Competitive Advantage:

Dual Axis Galvanometer Optical Scanners,competitive price , good quality, delivery on time, providing perfect after-sales service, to provide customers with professional customized products of parameter. We will supply you with best solution.

More about us:

Established in 2008, We Giai photonics Co.,Ltd is a leading supplier of precision optical components, designing and manufacturing a wide array of optical filters, multi-element lenses, lens coatings. We do this with skilled technicians, expert engineers, and modern optical fabrication equipment, the latest metrology. Our objective is to offer the finest quality precision components, optics and systems available to meet the service requirements and exceed the expectations of our customers.

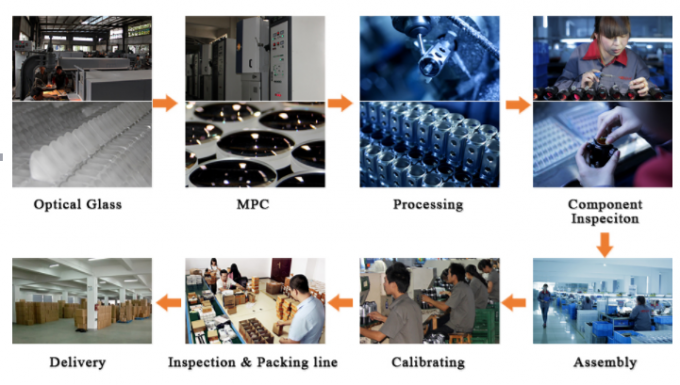

Manufacture Procedures:

Our Advertanges:

1. Fast Feedback: We are on line 24hours and give prompt reply in 12hours.

2. Short Delivery Time: We could process and delivery for you in shorttest time.

3. Reasonable Price: We reject unrealistically low price. As a prerequisite to ensure the highest quality of the products and provide the reasonable price.

4.Quality Ensurance: Experience team and efficent equipment are the important guarantee for the products.

5.Convenient Logistics Service: We cooperate with famous express logistics company cover 90% regions of the world and ensure products could be deliveried to customers safly and quickly.

6. Amount of Inventory: We have amount of standard optics inventory can supply for you, which save lots of money and time.

Shipping Methods:

Why Choose Us:

| Q1. How many days will samples be finished? How about mass products? |

| A1. Generally, our items are produced base on customer’s drawings. So the lead time of the sample order will be similar to mass production order. |

| Q3. How do you control the quality of your optical glass lenses? |

| A3. Optical glass lenses are processed in the vacuum dust-free workshop, the processing technology includes material preparation, milling and grinding, precision grinding, polishing, rinsing, edging, coating, inspection and agglutination. |

| To guarantee high-quality of lenses, each processing will be inspected during the processing transfer. |

| Q4. Are you a factory? |

| A4. Yes, we are a factory with 10 years experience, and there are about 300 employees in our factory. |

| Q5: What is the packing and shipping? |

| A5: Normally we will pack the items in vacuum electrostatic packaging, then pack them in an outer box. |

| Q6: What is your warranty? |

| A6: We provide 1 year warranty to all our customers. |

Please do not hesistate to contact us if there is any inquiry or demand.

We will response you in 24 hours!