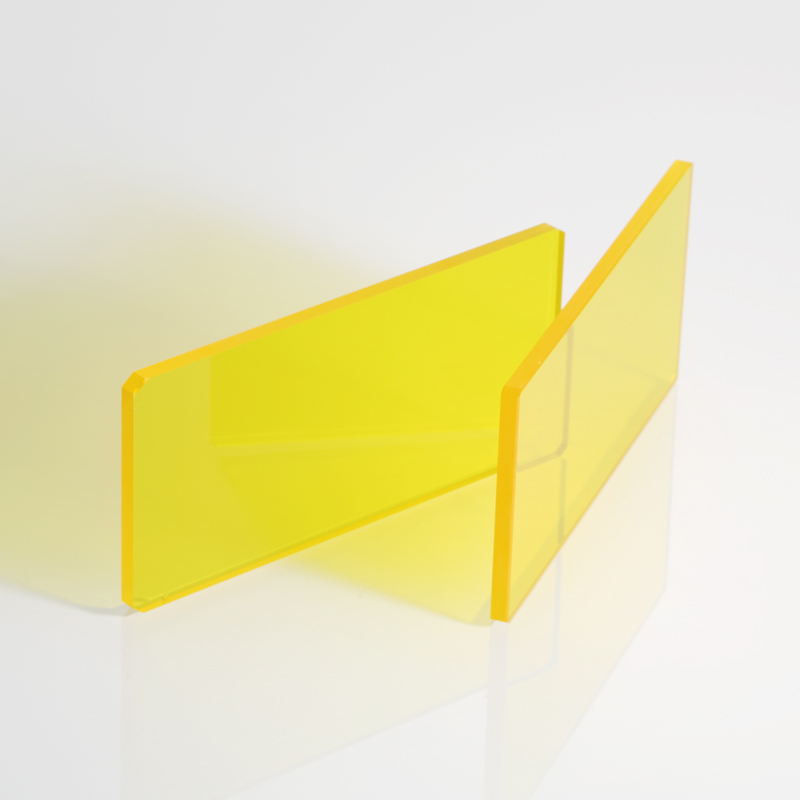

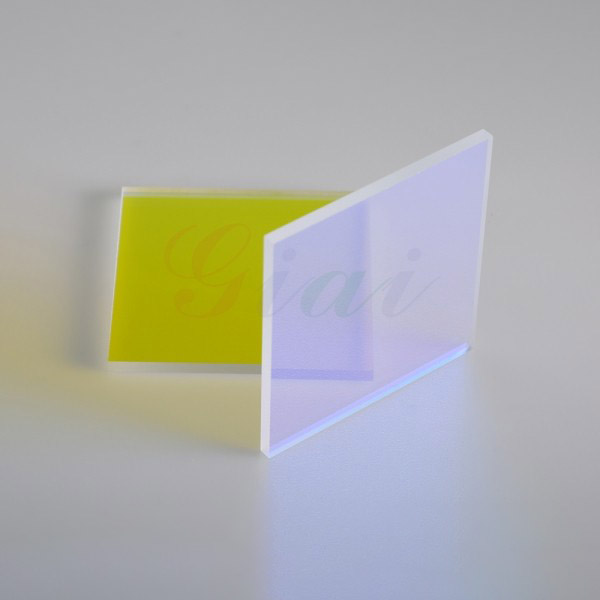

QB18+AR is a colored glass product with AR coating on cyan blue glass of brand QB18. By combining cyan blue glass with AR coating, it not only retains the unique visual effect of cyan blue glass, but also enhances its optical performance through the application of AR coating. Product FeaturesBlue blue glass base: QB18 uses cyan blue glass as the product base. This color gives people a fresh and peaceful feeling and is suitable for a variety of decoration and design scenes. AR coating: AR coating (anti-reflective film) is coated on the surface of cyan blue glass. The main function of this film is to reduce the reflection of light on the glass surface and increase the light transmittance.

Model:QB18+AR Glass

Specifications: Customized

Material: Optical glass

Product Introduction

QB18+AR is a colored glass product with brand QB18 cyan glass coated with AR film. By combining cyan glass with AR film, it not only retains the unique visual effect of cyan glass, but also enhances its optical performance through the application of AR film.

Product Features

Cyan-Blue glass substrate: QB18 uses blue-blue glass as the product substrate. This color gives people a fresh and tranquil feeling and is suitable for a variety of decoration and design scenarios.

AR coating: AR film (anti-reflective film) is coated on the surface of Cyan-Blue glass. The main function of this film is to reduce the reflection of light on the glass surface and increase the transmittance. Especially in the two specific bands of 420nm (blue light band) and 540nm (green light band), QB18+AR has good transmittance characteristics, which means that it has higher light transmittance in these bands and more accurate color reproduction.

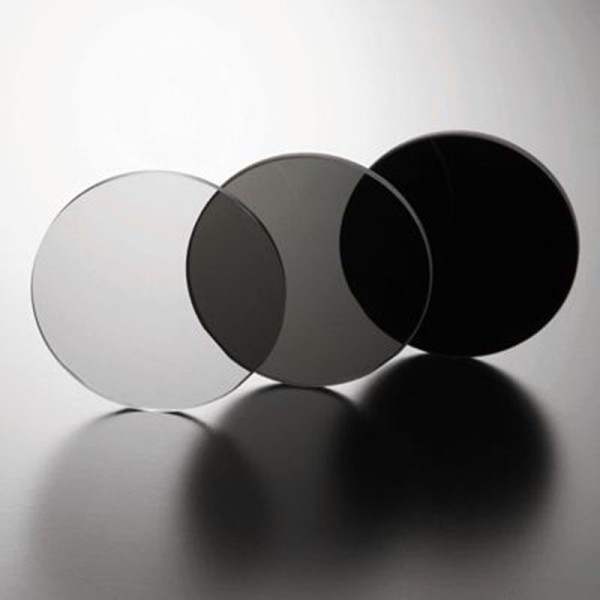

Thickness and customization: The default thickness of the product is 2mm, but the thickness can be customized according to customer needs. This flexibility makes QB18+AR suitable for more diversified application scenarios.

Excellent streaks and stress values: The streaks and stress values are strictly controlled during the manufacturing process of the product to ensure the optical performance and appearance quality of the product. Low streaks and low stress values mean that the product is not prone to deformation, distortion or optical distortion during use.