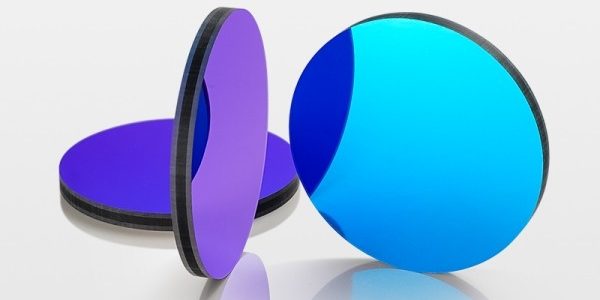

As an important optical component, optical filters are widely used in scientific research, medical treatment, industry and other fields. In the production process of filters, there is a significant difference in cost between customized filters and standard filters. This article will explore the reasons for the huge cost gap between customized filters and standard filters from multiple aspects such as material cost, production process and scale benefits, market demand, and customization cost.

Material cost

There is a significant difference in material selection between customized filters and standard filters. Since customized filters are designed and manufactured according to customer-specific needs, they have greater flexibility in material selection. Customers may require the use of high-quality or rare materials such as special glass, crystal, sapphire, germanium, etc., which are expensive in themselves, thereby increasing the material cost of customized filters. In particular, the price of upstream raw materials has risen in recent years, especially the price fluctuations of rare materials such as germanium, which further increases the material cost of customized filters.

In contrast, standard filters are usually produced with standardized materials, which are in sufficient supply on the market and have relatively low costs. Therefore, standard filters have an advantage in material cost.

Production process and scale benefits

Production process and scale benefits are also important factors affecting the cost difference between customized filters and standard filters. The production process of customized filters is complex and changeable, because each filter is unique and needs to be customized according to the actual needs of customers. This customized production method leads to low production efficiency and difficulty in large-scale production, which increases production costs.

Standard filters adopt standardized production processes, which can achieve large-scale batch production. Large-scale production helps to reduce the manufacturing cost of unit products and improve efficiency, thereby forming a competitive advantage in price. In addition, the production process of standard filters is relatively simple, and due to the large production scale, large-scale production can be achieved, further reducing the manufacturing cost of unit products.

Market demand and customization cost

Market demand and customization cost are also one of the reasons for the cost difference between customized filters and standard filters. The market demand for customized filters is relatively small and diverse, because each customer’s needs are unique. This makes it difficult for manufacturers to form economies of scale and increases production costs. At the same time, due to the uncertainty of customized demand, manufacturers need to bear certain inventory risks and market risks. These factors will be reflected in the product price, making the price of customized filters higher.

However, the market demand for standard filters is relatively stable and large-scale, so manufacturers can form economies of scale and reduce production costs. Standardized products are more likely to meet market demand, reduce inventory risks, and thus be more competitive in price.

Other factors

In addition to the above factors, there are some other factors that will affect the price difference between customized filters and standard filters. For example, customized services themselves require more manpower, material and financial resources to meet the personalized needs of customers. This includes the cost investment in multiple links such as design, production, and testing. Standard filters can reduce costs by optimizing production processes and improving production efficiency.

In addition, factors such as market competition and brand influence will also affect prices. In the fierce market competition, in order to maintain competitiveness, some manufacturers may attract customers by lowering prices. Manufacturers with greater brand influence may maintain price advantages by improving product quality and service levels.

Conclusion

In summary, the cost difference between customized filters and standard filters is mainly due to the influence of material costs, production processes and economies of scale, market demand and customization costs, and many other factors. When choosing filters, customers should weigh and choose according to their actual needs. Although customized filters that require special materials or special processes are more expensive, they can meet the specific needs of customers. For customers who are price-sensitive and have relatively stable demands, standard filters can be selected to reduce costs.

With the development of science and technology and the continuous changes in market demand, the production technology and market demand of filters will also continue to develop and change. In the future, filter manufacturers need to continuously innovate and optimize production processes, improve product quality and service levels to meet the changing needs of customers. At the same time, it is also necessary to strengthen market research and forecasting, accurately grasp the changing trends of market demand, and formulate reasonable production plans and pricing strategies.